ACA RoQ and ACA RoQ Inline are innovative tools that specialize in measuring roll hardness profiles, which play a critical role in diagnosing and enhancing roll manufacturing, converting, and finishing processes.

The advanced technology incorporated ensures precise measurements and offers seamless data transfer and storage options. The roll hardness profile serves as a fundamental parameter for determining the quality of a roll.

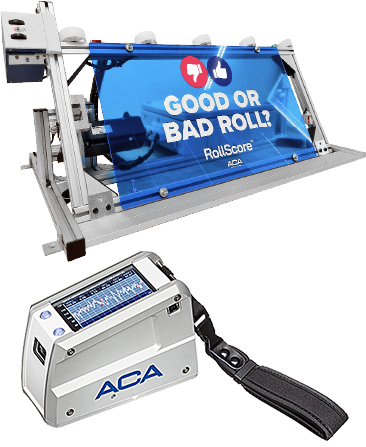

ACA RoQ Inline is a convenient automated analyzer that can be directly installed in the production line. The handheld ACA RoQ, with distinctive features like an integrated touch screen, Wi-Fi capability, and a built-in barcode reader, stands out in its field.

Both analyzers represent a cutting-edge advancement in accurately characterizing roll profiles. Through a straightforward measurement procedure, they effortlessly generate reproducible high-resolution profiles, contributing to the consistent evaluation of roll quality.