Quality control as the enabler of cost and performance – optimized water-based barrier coated (WBBC) paper

Water-based barrier coated (WBBC) paper has made significant progress as a sustainable alternative to plastic films. However, its widespread adoption is not limited by cost alone, but by the ability to deliver the required barrier performance at competitive cost.

While the environmental case is compelling, market acceptance ultimately depends on achieving a reliable balance between performance, productivity, and material efficiency.

Water-based barrier coated (WBBC) paper is a sustainable, recyclable, and biodegradable alternative to plastic or wax coatings, mainly used in food packaging.

In food and packaging applications, deviations from specification cannot be corrected by re-grading or pricing adjustments. A single failure may result in the rejection of an entire production lot, including penalties, wasted material, and lost production time. This makes quality control a decisive factor—not only for compliance, but for economic viability.

As WBBC moves into cost-sensitive, high-volume applications, quality management must evolve from reactive end-product testing toward process-oriented, preventive control.

Based on this requirement, ACA Systems has developed a three-pillar quality-control concept that directly addresses the cost–performance challenge of WBBC production.

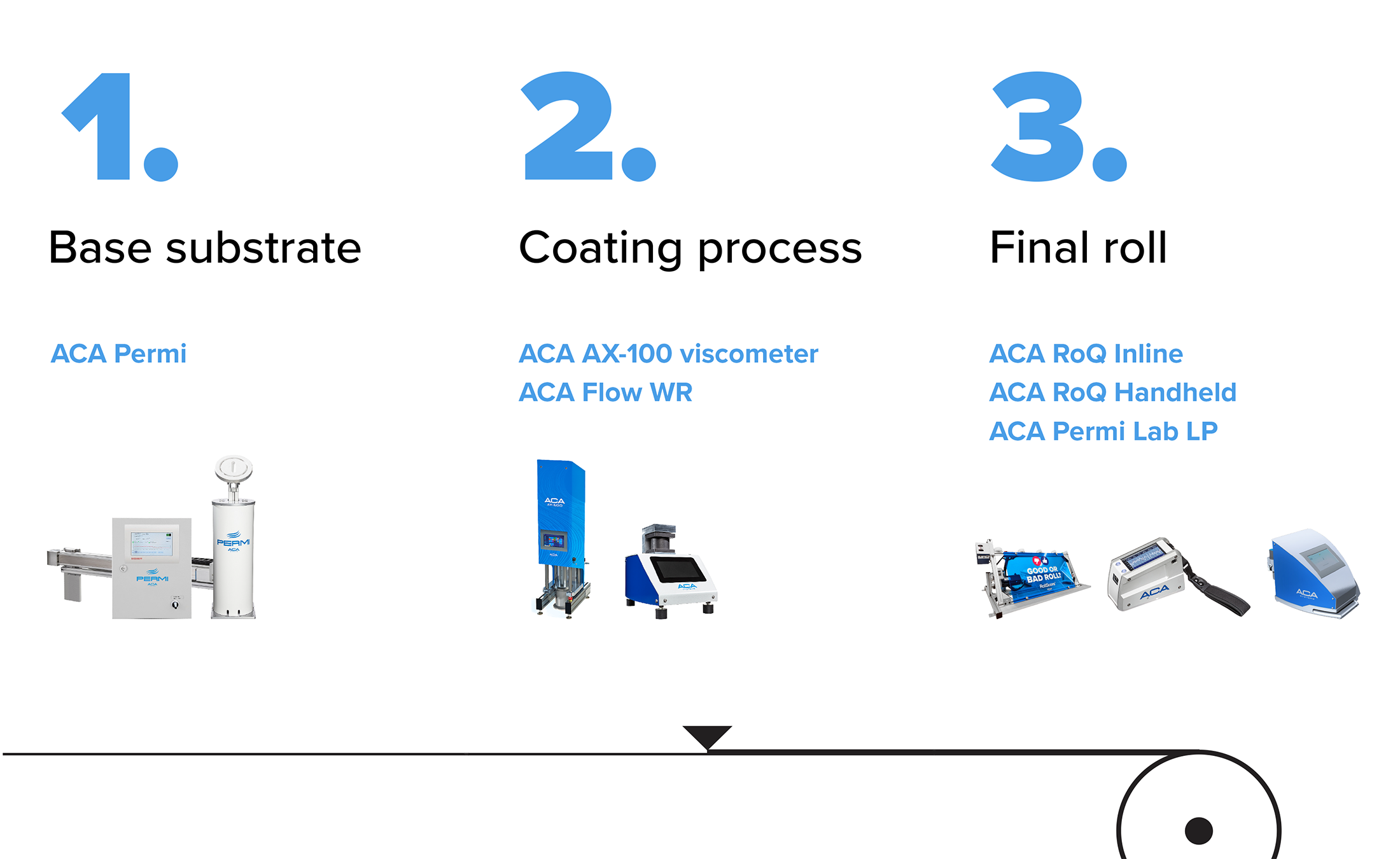

The three pillars of WBBC quality control

Consistent WBBC performance rests on three sequential and interdependent pillars:

Base substrate – establishing a stable and predictable starting point

Coating process – ensuring formulation and application stability under real operating conditions

Final roll – verifying uniformity and quality of the product delivered to the converter

Only when all three pillars are controlled in a coordinated manner can WBBC producers achieve stable barrier performance, minimal waste, and competitive production costs at industrial scale.

The three pillars of WBBC quality control, supported by ACA Systems analyzers at each critical stage.

Pillar 1: Base substrate – stabilizing the starting point

The porosity and structure of the base paper strongly influence coating holdout and barrier formation. Even small variations in air permeance can lead to differences in coating demand and final barrier performance.

With online air permeance measurement using ACA Permi, substrate variations can be detected before coating. This enables real-time process adjustments, reduces corrective actions downstream, and supports consistent coating application with optimized material usage.

Real-time air permeability and porosity measurement with ACA Permi.

Pillar 2: Coating – process-relevant control

Barrier properties are typically verified using standardized methods such as WVTR testing. While essential, these tests are slow, with results often available only long after production.

For operational quality control, manufacturers therefore rely on process-relevant coating measurements. High-shear capillary viscosity has proven to be a reliable indicator of coating color quality and formulation consistency.

The ACA AX-100 viscometer is designed to mimic real process conditions using alternative pressure ranges and dye selection, allowing measurements to be tailored to specific applications.

The AX-100 provides a range of capillaries for shear viscosity measurement, as well as an orifice dye for extensional viscosity. This enables control of both shear and extensional flow behavior—particularly important in curtain coating, where extensional flow stability directly affects coating uniformity and defect formation.

In complex coating kitchens, even a single off-spec component can affect barrier performance. Continuous viscosity monitoring, from dispersion preparation to the approach system, helps detect such deviations early.

In addition, water retention behavior plays a critical role during application. The ACA Flow WR enables reliable monitoring of water retention value, supporting stable coating runnability and uniform layer formation.

Pillar 3: Final roll – uniformity and verification

The mechanical condition of the finished roll influences coating integrity and downstream converting performance.

Non-uniform roll hardness can result in defects during slitting, printing, or storage. Roll hardness measurements are known to correlate well with thickness variations across and along the roll and therefore provide a practical overall assessment of roll uniformity—a key quality parameter for the converter. Roll hardness profiles can be measured using ACA RoQ Handheld for spot checks or ACA RoQ Inline for continuous monitoring during winding.

While full barrier testing remains indispensable, fast verification methods support daily quality decisions. The ACA Permi Lab LP 300 air permeance tester allows quick assessment of preliminary barrier properties, helping to identify trends and deviations without long waiting times.

Fast and flexible quality control with ACA RoQ Handheld.

From reactive to preventive quality control

As barrier-coated paper moves into cost-sensitive, high-volume applications, quality control must become faster, more predictive, and more closely linked to the process. Aligning measurement technology with the three pillars—base substrate, coating, and final roll—helps reduce risk, minimize waste, and ensure consistent product quality.

About ACA Systems

ACA Systems supports manufacturers of paper, board, and packaging materials with specialized measurement technology and application expertise.

Our portfolio of analytical tools covers key quality parameters—from substrate porosity and coating rheology to roll hardness and barrier verification. By combining reliable instrumentation with deep process understanding, ACA Systems helps customers turn measurement data into actionable insight for stable, efficient, and cost-effective production.

Get in touch or leave us a contact request, and let’s discuss your specific needs and how our solutions can help optimize your production.