Advanced roll quality control: reducing costs and enhancing converting performance

What if you could cut customer complaints by up to 40% – and reduce runnability issues by 30% – all with a fast return on investment?

In roll manufacturing industries such as paper, plastic foil, and aluminum foil, maintaining high roll quality is crucial. With increasing customer demands and tighter converting tolerances, ensuring consistent roll quality throughout production is more important than ever. Poor roll quality can lead to significant hidden costs, including waste, machine downtime, and customer complaints.

Roll quality challenges faced by manufacturers

Manufacturers often face challenges related to roll hardness variation, which can lead to wrinkling, telescoping, poor unwinding, and web breaks. These inconsistencies are often present from the mother roll to the final slit rolls. Without proper tools to monitor and measure roll hardness, maintaining consistent quality is difficult.

The role of hardness profiles in roll performance

Roll hardness profiles are one of the most critical factors in converting performance. Uniform hardness not only ensures smooth unwinding and stable web tension but also minimizes the risk of defects that cause stoppages, scrap, and lost productivity. Consistent profiles help operators run lines at optimal speed without compromising quality, improving the efficiency and predictability of downstream operations.

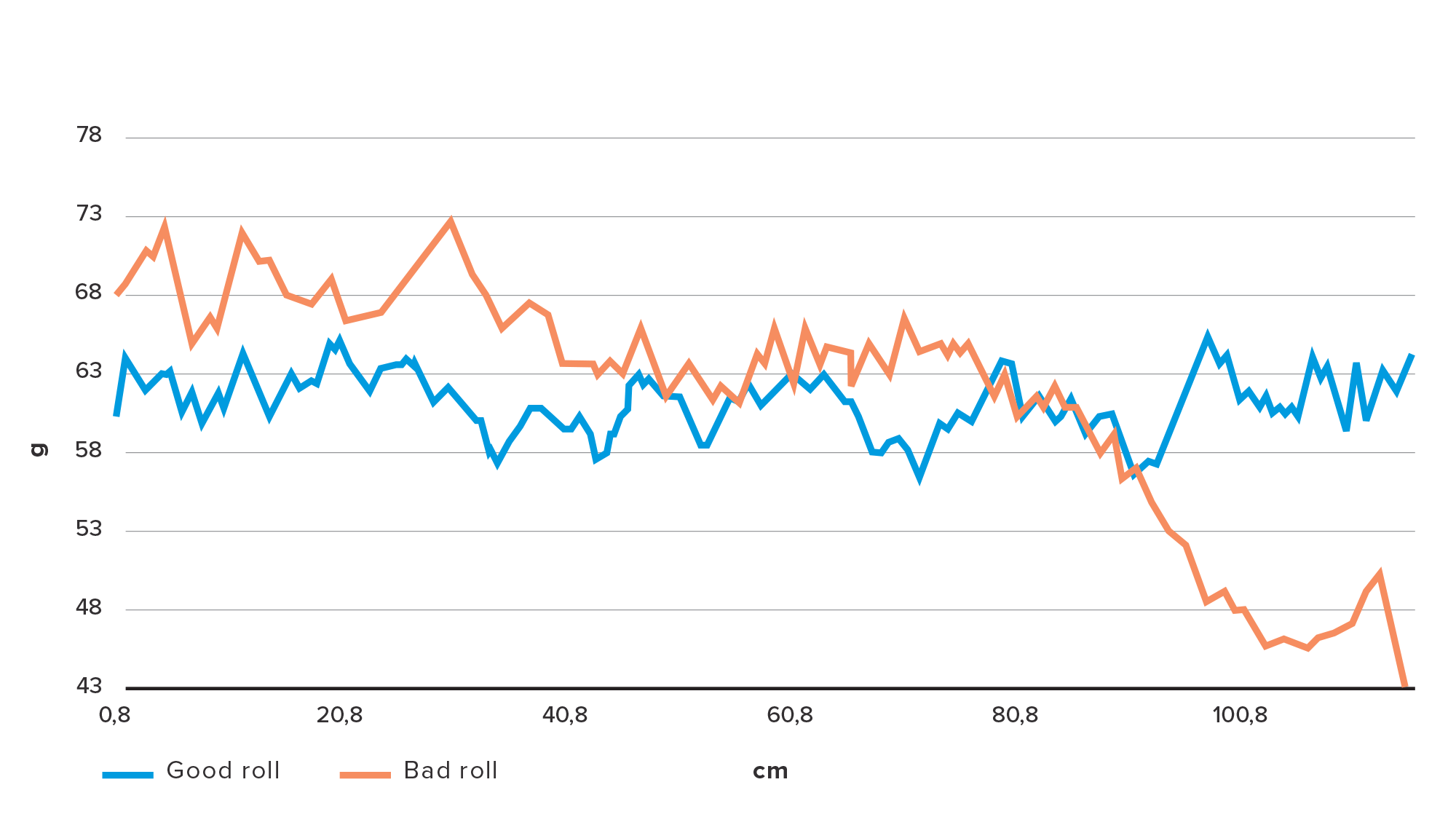

Roll hardness profile shows whether the roll is good or bad.

By detecting winding errors or internal roll defects early, manufacturers can take corrective action before problems escalate – preventing waste, avoiding customer complaints, and safeguarding brand reputation. In many cases, accurate hardness profiling can turn reactive troubleshooting into proactive quality assurance, delivering both operational and financial gains.

Advanced tools for modern roll QA

ACA offers two advanced solutions for roll quality control:

ACA RoQ Handheld

The ACA RoQ Handheld is a portable device used for on-site measurement of roll hardness. It is ideal for sampling mother rolls and performing quality checks at various stages of production. This allows for early detection of issues, enabling timely corrective actions.

ACA RoQ Inline

The ACA RoQ Inline system provides continuous roll quality monitoring during production. It delivers real-time data on roll hardness profiles, enabling automatic detection of anomalies. This system supports complete roll documentation and traceability, which enhances customer confidence and supports quality certifications.

ACA RoQ Inline delivers real-time data automatically.

Reducing costs and enhancing converting performance

By replacing subjective visual checks with accurate, data-driven measurements, manufacturers have achieved:

significant reductions in roll quality costs through fewer returns and complaints

improved converting line efficiency with less downtime

clear, objective quality records for every roll

greater customer satisfaction and trust through full roll documentation

One manufacturer reported us a 40% drop in customer complaints after installing the ACA RoQ Inline system. That's a direct boost to customer satisfaction, loyalty, and long-term business.

Conclusion

Shifting from subjective inspections to automated, data-driven quality control is no longer optional – it’s essential for competitive roll manufacturing. The ACA RoQ Handheld and Inline systems give you the precision, consistency, and insight needed to produce high-quality rolls every time. The result: lower production costs, fewer quality issues, and stronger, more trusted customer relationships.

If you’re ready to see how ACA RoQ can optimise your manufacturing process, our team is here to help. Let’s start the conversation.

Read more about ACA RoQ