Roll hardness measurement with ACA ROQ Inline – the new standard in roll quality control

ACA RoQ Inline.

In today’s competitive production environment, paper, board, plastic film, and converting industries face growing demands for higher quality, fewer defects, and greater efficiency. Consistency in roll hardness is a critical factor in meeting these demands, as variations in hardness profiles can lead to production losses, customer complaints, and unnecessary waste.

ACA ROQ Inline introduces a breakthrough solution: continuous and automatic inline roll hardness measurement. Unlike traditional offline sampling methods, ACA ROQ Inline measures every customer roll produced, providing real-time feedback and ensuring that roll quality is always under control.

Real-time roll quality control with ACA RoQ inline.

Continuous and Accurate Roll Quality Control

The key benefit of ACA ROQ Inline lies in its ability to deliver continuous roll profile control with unmatched accuracy. Instead of checking a limited sample, mills gain full visibility over all rolls, enabling immediate detection of deviations. This ensures more stable production, consistent product quality, and higher customer satisfaction.

With automatic measurement integrated into the process, operators can:

Reduce roll quality variations significantly

Minimize customer claims related to roll defects

Improve overall production output by avoiding unnecessary rework

Proven Results: 40% Reduction in Hardness Variation

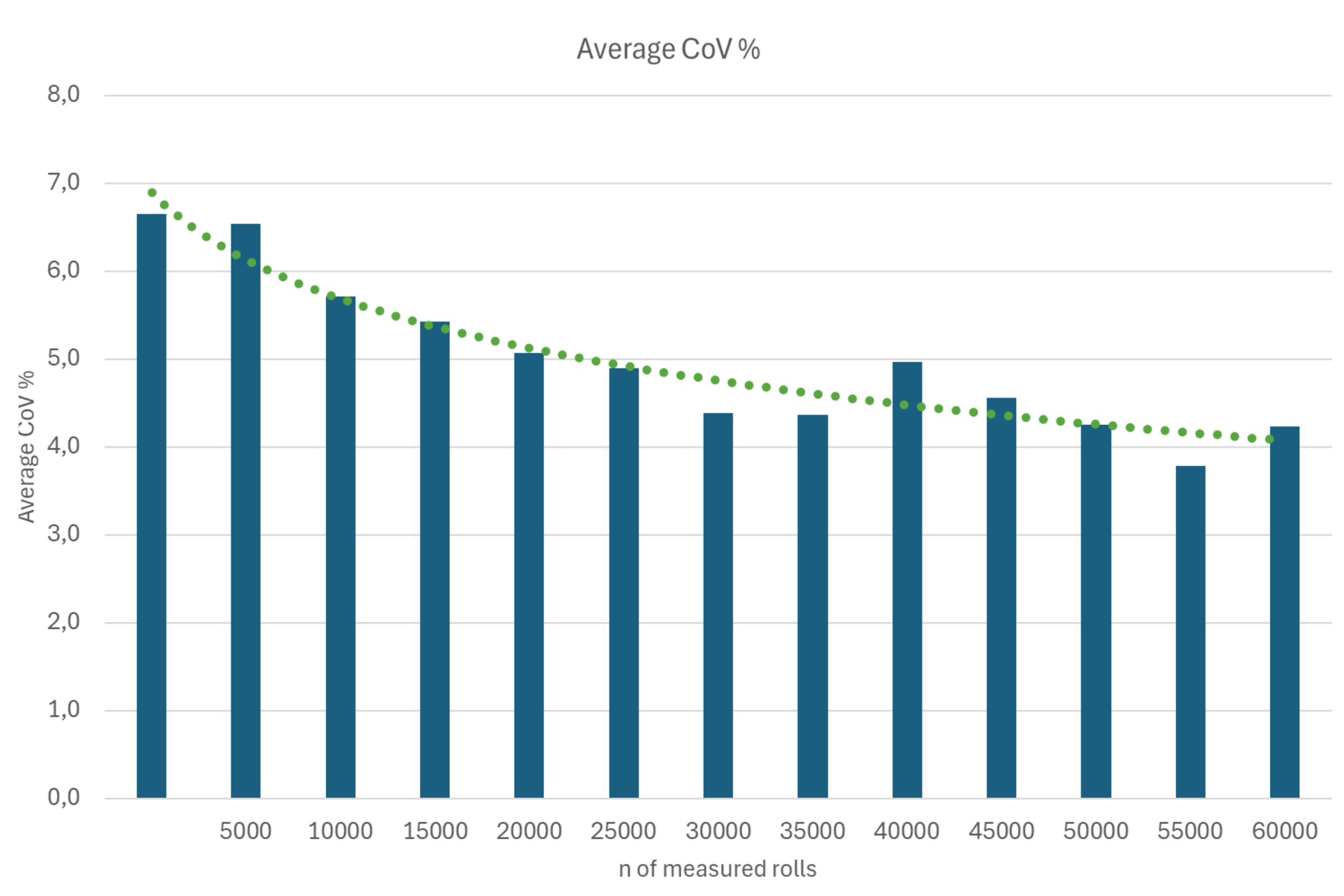

One of the most compelling results comes from a recent customer case. The graph below illustrates how ACA ROQ Inline improved roll hardness consistency across thousands of rolls.

The average Coefficient of Variation (CoV) of roll hardness profiles was reduced by 40% after implementation.

This improvement directly translates to more uniform rolls, fewer downstream issues, and greater efficiency for both the mill and its customers.

The dotted green line in the figure shows the decreasing trend of CoV as more rolls are measured and controlled inline. The data demonstrates that with ACA ROQ Inline, roll quality variations become progressively smaller, leading to a more stable production process.

The New Benchmark for Roll Quality

With ACA ROQ Inline, mills no longer have to rely solely on manual spot-checks or offline testing. Every roll is automatically verified for hardness consistency, setting a new benchmark for quality assurance.

Key benefits for customers include:

Continuous, automatic quality control of every roll

40% reduction in roll hardness variation

Fewer customer complaints and claims

Increased output and production efficiency

The most accurate roll profile control solution available today

Conclusion

ACA ROQ Inline represents the next step in roll quality management. By providing continuous, automatic, and highly accurate roll hardness measurement, it helps mills reduce variation, increase customer satisfaction, and improve efficiency. For manufacturers seeking the best possible roll quality and competitive advantage, ACA ROQ Inline is the clear choice.

Ready to take roll quality control to the next level? Let’s start the conversation.

Meet us at K 2025

Come and see novel ACA ROQ Inline at K-messe Düsseldolf. You can find us in Hall 11, booth E50, together with our partner R.A.M. GmbH.

ACA RoQ Inline product page